Plastic pipes are built to last—and that’s exactly what makes them a smart choice for sustainable infrastructure. Unlike single-use plastics, pipes are engineered to deliver reliable performance for more than 100 years. Their long service life reduces waste, maximises resource efficiency, and ensures materials stay in use for as long as possible at their highest value. By using resources responsibly and sustainably, plastic pipes support smarter, more resilient infrastructure.

Plastic pipes can be repaired, reused, and fully recycled at end-of-life, closing the loop and turning a long-life product into a long-term sustainability solution.

Plastic pipe manufacturing is a straightforward and efficient process. The main inputs are plastic pellets or powder and electricity. Because production equipment and heating are electrically powered—and only relatively low temperatures are needed to melt the plastic—the process is clean and enclosed. No combustion or chemical reactions are involved, meaning there is no smoke and no harmful emissions generated during manufacturing.

Plastic pipes begin as thermoplastic pellets or powder, which are fed into a heated barrel and melted using electricity at around 160–200°C. The molten material is then pushed through a shaped die, forming the pipe’s round shape. It’s cooled quickly to lock in size and strength and finally cut to the right length—ready for use in durable, long-lasting infrastructure.

Pipe manufactures reuse production rework in both pressure and non-pressure pipes, diverting waste from landfill – making better use of resources. While rework is reused, it is not classified as recycled content.

Plastic pipes are designed to last over 100 years, which means only a small amount of recycled material is currently available. Yet the industry is driving real circular solutions—keeping valuable materials out of landfill, recovering off-cuts, providing disposal options, and educating users on responsible practices. These efforts are closing the loop, supporting smarter resource use, and reducing environmental impact across the built environment and infrastructure sectors.

Plastic pipes aren’t one-size-fits-all—they’re precision-engineered for performance. Recycled content can be used, but it must meet the same rigorous standards as virgin material. Australian Product Standards define exactly what materials are suitable for different applications, especially in critical infrastructure where failure is not an option. No matter the source, every pipe is built to last and fit for purpose.

Download our guideline POP208 on specification and testing guidelines for recycled materials

Post-consumer 1 & 2

Plastics material generated by households, or by commercial, industrial and institutional facilities, in their role as end-users of the product that have fulfilled their intended purpose or that can no longer be used.

Pre-consumer 1,2 & 3

Plastics material diverted from the waste stream during a manufacturing process or from unused products. This excludes a manufacturer’s own rework, regrind or scrap.

1 – Definition is based on AS 14021 Environmental labels and declarations – Self declared environmental claims (Type 2 Environmental Labelling) (ISO 14021:2016MOD).

2 – Definition is based on CEN/TS 14541.1 Plastics pipes and fittings – Utilisation of thermoplastics recyclates Part 1 Terminology.

3 – Previously defined as Post-Industrial.

Sandwich Construction (SC) PVC-U allows manufacturers to combine their own rework with post- and pre-consumer PVC waste in the pipe’s core layer for non-pressure pipes. This approach helps divert valuable PVC from landfill while producing new pipes that meet the same performance and lifespan standards as those made from virgin materials.

One of the strengths of plastic pipe design is its flexibility. While Australian Standards for pressure pipe applications restrict the use of post-consumer recyclate—due to potential impacts on drinking water or structural performance—many pipe types can readily incorporate it. For example, multilayer PVC drainage and conduit pipes, as well as PE drainage pipes, already use post-consumer recyclate as feedstock.

Whenever post-consumer recyclate is used, the material must meet all relevant Australian Standards, ensuring the pipe’s performance and strength are fully maintained.

Even though the overall volume of end-of-life plastic pipes is low, there are opportunities to recycle off-cuts from installation and pipes that reach end-of-life earlier than expected. The industry has been proactive in monitoring and establishing pilot programs to reduce environmental impact and recover valuable resources.

A NSW Government audit of construction and demolition waste found that at one landfill site handling 600,000 tonnes of material, just 1,000–3,000 tonnes were plastic pipes—that’s only 0.1–0.5%!

Why so little? Because plastic pipes are built to last. With a service life of 100 years or more, most are still in their first life cycle today. That durability is exactly why they’re such a smart choice for building and infrastructure projects.

Did you know plastic pipes make up just 0.004% of the material passing through recycling centres?

Back in 2005, PIPA joined a three-month pilot in Sydney to explore how plastic pipes from demolition and construction waste could be collected and recycled. Across four recycling centres processing around 8,000 tonnes of waste per week, the trial revealed that:

Even from a small volume of waste, this pilot showed the real potential for recycling plastic pipes and laid the groundwork for ongoing industry initiatives.

Full life cycle assessments show plastic pipes perform sustainably across their entire lifespan. Their production is also energy-efficient, low-emission, and has a minimal carbon footprint—combining performance with environmental responsibility.

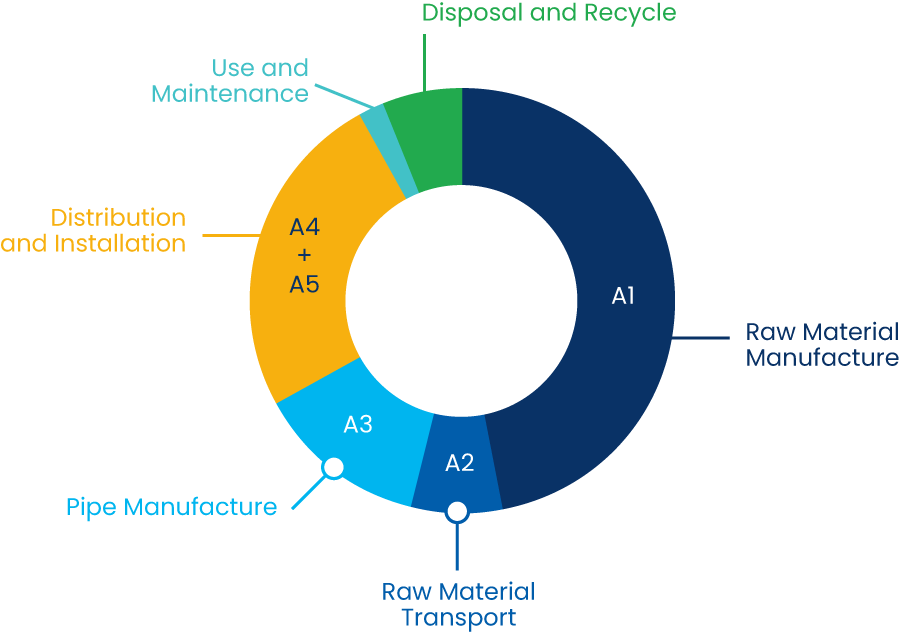

When we look at a plastic pipe over its entire life cycle, the largest environmental impacts occur during the Product Stage.

The chart above shows the Global Warming Potential (kg CO₂ eq) for PVC, PE, and PP pipe systems, based on our Australian EPDs.

Quick context on greenhouse gases:

Key insights from the life cycle:

The Product Stages (A1, A2, A3) contribute about 70% of the total global warming potential, with raw material manufacture being the largest factor.

This approach shows how plastic pipes combine long service life with a manageable environmental footprint, especially when focusing on material choices and responsible end-of-life planning.

Using third-party verified EPDs tailored to Australian conditions, two independent LCAs comparing PE, PP, PVC-M, and PVC-O pipes with traditional materials like steel-reinforced concrete and ductile iron were undertaken to better understand their environmental impacts.

These assessments looked at all impact categories including carbon emissions, water use, energy, and recyclability across the full life cycle. While no material is perfect in every category, plastic pipes deliver strong sustainability benefits—particularly in reducing embodied carbon and water use—providing reliable, local data to support smarter infrastructure choices.

This report compares the life cycle impacts of plastic drainage pipes—corrugated PE and PP—against steel-reinforced concrete (SRC) pipes for common sizes DN 375, DN 600, and DN 900. The results highlight plastic pipes as a lower-impact alternative, especially for reducing embodied carbon and water consumption.

Plastic pipes emit 12–32% less CO₂ than concrete pipes across all sizes—from DN375 to DN900.

Plastic pipes use up to 56% less freshwater during manufacturing, making them a better fit for Australia's water-sensitive environment.

Lighter weight means 26–67% lower transport-related emissions compared to heavy concrete pipes.

Designed for 100-year use, plastic pipes are fully recyclable. Although the study focused on virgin resin, adding just 10–30% recycled content can substantially lower the carbon footprint.

Download the summary report: Environmental performance comparison – Plastic and concrete pipes in drainage applications.

This report compares the life cycle impacts of plastic pipes—PE, PVC-M, and PVC-O—against traditional ductile iron cement-lined (DICL) pipes for water applications, focusing on common sizes DN100 and DN300.

The findings indicate plastic pipes offer notable environmental advantages, including lower greenhouse gas emissions, significantly reduced water consumption, and minimal radioactive waste. These benefits, combined with lighter weight and local production advantages, highlight plastic pipes as the environmentally smarter choice for building climate-resilient infrastructure.

Plastic pipes produce significantly fewer greenhouse gases during manufacturing. For example, DN100 PVC-O pipes emit just 7 kg CO₂-eq per metre, compared to 37 kg for DICL pipes.

In a country where every drop counts, plastic pipes require up to 80% less freshwater during production—a critical advantage for Australian sustainability goals.

Lighter and often produced locally, plastic pipes have a smaller transportation footprint than heavier, imported DICL alternatives.

Plastic pipes outperformed DICL in most high-priority environmental indicators, including global warming potential, water usage, and ozone creation.

Download the summary report: Comparative Environmental Assessment – Plastic and Ductile Iron (DICL) pipes in Infrastructure applications.

Environmental Product Declaration (EPD) are an independently verified documents that explains the environmental impact of a product over its whole life cycle. Based on a Life Cycle Assessment (LCA), it provides transparent and measurable data on resource use, emissions, and other impacts. This allows end users, specifiers, and stakeholders to easily compare products and make informed, sustainable choices.

Comparing EPDs across different pipe materials or suppliers requires careful attention to consistency, methodology, and scope to ensure a meaningful and fair analysis:

Confirm that the products being compared serve the same function (e.g., drainage, pressure capacity) and have similar service lives. Without this, results may reflect performance discrepancies rather than material impacts.

EPDs must use the same declared unit (e.g., per metre of pipe) for a valid comparison. Differences in units can significantly distort comparative results.

Ensure that the EPDs cover equivalent life cycle stages. This study uses cradle-to-installation (A1–A5). Some EPDs may only include cradle-to-gate (A1–A3), which can underestimate total impacts.

LCA results vary based on data sources. For example, resin data in plastic pipe EPDs may reflect global averages, whereas concrete EPDs might use locally sourced information. For accurate comparisons, data origin and type (primary vs. secondary) must be aligned.

Check that EPDs follow the same methodological framework (e.g., EN 15804+A2). Older EPDs using EN 15804+A1 or ISO 14025 may not be directly comparable due to differences in impact assessment approaches.

Confirm that the EPDs include the same set of environmental indicators, such as global warming potential (GWP), water use, eutrophication, and waste generation. Gaps in impact categories may skew comparison.

Some materials like concrete incorporate significant recycled content (e.g., steel reinforcement), whereas plastic pipes currently use virgin resins. Understanding how recycled content is treated in each EPD is essential for fair evaluation.

For more than 50 years, plastic pipes have been the backbone of modern water, sewer, gas, and conduit systems. Their popularity isn’t just about performance and durability—it’s also about environmental benefits. Plastic pipes are lightweight, long-lasting, and efficient to produce and transport, which helps reduce energy use and emissions across their life cycle.

If plastic pipes were no longer available, we’d have to return to older materials. Many of these alternatives are heavier, less efficient to install and maintain, and in some cases are no longer acceptable due to performance or safety concerns. This would mean higher environmental impacts, greater use of resources, and less sustainable outcomes for essential infrastructure.

Plastic pipes are affordable because they need less energy to make, transport, and install. Using less energy not only reduces costs but also cuts CO₂ emissions and saves valuable resources like coal, oil, and gas.

Thanks to their durability, plastic pipes don’t corrode and have an exceptionally long service life. This means fewer replacements, less maintenance, and less waste over time—and at the end of their life, they can be recycled.

Plastic pipes are designed to perform better in real-world applications. They often use less energy during operation and can provide superior protection systems, such as in communication conduits.

Why Old Pipe Materials Aren’t the Answer

Once widely used for drinking water, asbestos cement pipes are no longer acceptable. Over time, they crack with soil movement, and repairing them poses serious health risks due to asbestos fibres.

Lead pipes were once common in household plumbing, but we now know they are unsafe and completely unsuitable for carrying drinking water.

Clay pipes were often used in sewer systems, but they cracked easily, leaked, and were prone to root intrusion. Poor joints and frequent blockages meant costly and ongoing repairs.

That leaves us with iron, steel, or copper—but none of these are ideal alternatives. Iron and steel are strong, but they’re heavy, expensive to install, and prone to corrosion, often leading to burst pipes, wasted water, and flooding. Copper, while durable, comes with a high price tag and rising costs due to increasing demand in cabling, electronics, and electric vehicles.

Without plastic pipes, the environmental impact would be significant

Alternative materials need much more energy to produce and transport. Heavier pipes mean more fuel, more CO₂ emissions, and greater use of natural resources.

Modern irrigation systems rely on plastic pipes. Without them, many systems wouldn’t be viable, making food production less water-efficient. This would mean more water drawn from rivers, reducing flows and harming ecosystems and wildlife.

Plastic pipes have the lowest failure and leakage rates. Switching back to older materials would mean more bursts and leaks in water systems, wasting valuable water. In sewer systems, increased leakage would result in more environmental pollution.

In short, without plastic pipes, we’d face higher emissions, greater water waste, and more damage to the natural environment.