Engineered plastic pipes are designed to make a big difference in our lives while keeping their impact on the planet small. That’s why they’ve become the preferred choice for new and replacement pipes all over the world.

They’re made to the highest Australian Standards and are free from harmful substances like phthalates and heavy metals. With superior chemical resistance, they won’t rust or corrode like other materials—helping protect drinking water from contaminants and keeping it safe to enjoy.

Plastic pipes are built to last for generations without the need for routine maintenance. And unlike other materials, they don’t break down into microplastics or end up polluting our oceans and waterways.

The result? A reliable, sustainable, and trusted solution—safe for people, and safe for the planet.

Plastic pressure pipes manufactured to Australian Standards are rigorously tested to ensure they are safe for carrying drinking water. Clean water is essential for health and wellbeing, yet many take it for granted. From collection and storage to distribution, every step is carefully managed to protect this vital resource.

They’re designed to form a completely watertight system, preventing leaks and ensuring no contaminants enter the water. They are built to perform reliably throughout the lifetime of the infrastructure, keeping communities safe and healthy.

Plastic pipes and fittings tested to AS/NZS 4020 – ‘Testing of Products for Use in Contact with Drinking Water’ – meet one of the world’s most rigorous standards for ensuring a product is safe for drinking water.

The Standard ensures products:

From rigorous tasting panels and microbial tests to high-temperature trials and chemical screenings, every step ensures your water stays clean, safe, and healthy throughout the life of the pipe system.

Water quality is monitored constantly by all Water Agencies, ensuring that pipe networks deliver the highest standard of drinking water. Using plastic pressure pipes means choosing a system that supports this ongoing commitment to safety, reliability, and performance—so every tap in your home or business provides water you can trust.

Australia’s water quality guidelines provide a trusted framework to help agencies deliver drinking water that is safe, reliable, and fit for purpose. Updated regularly, these guidelines ensure water meets the highest standards for health and quality.

Phthalate-Free: Unlike flexible PVC, all Australian plastic pipes are made without plasticisers.

Dioxin-Controlled: While dioxins were historically a concern in PVC manufacture, strict production standards eliminate them from finished products. Best-practice emissions are far lower than other common sources.

Heavy-Metal-Free: Lead, cadmium, mercury, and hexavalent chromium are not sued in the production of plastic pipes. Plastic pipes are manufactured using safe calcium-zinc or organic stabilisers.

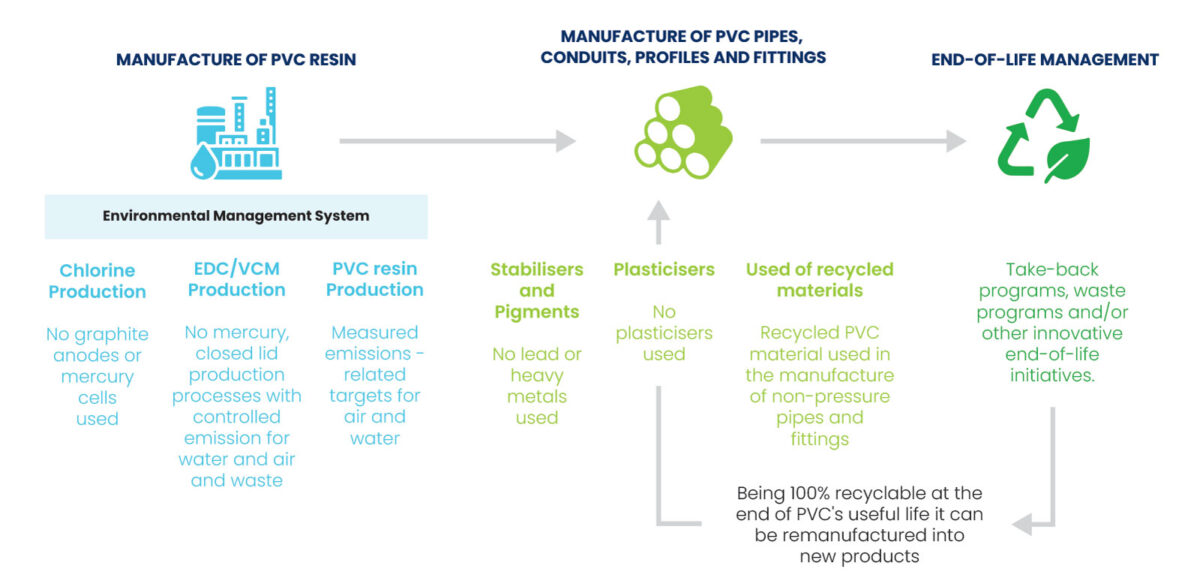

Best environmental practice (BEP) PVC is a reliable, safer, and more environmentally friendly way to produce PVC. It takes into account PVC’s whole supply chain from the production of PVC resin, use of additives, the manufacture of finished goods through to End of life (EOL) considerations.

Australia’s AS/NZS 5395 is the world’s only standard developed specifically for PVC pipe and fittings. All Australian PVC pipe manufacturers comply with this standard, and every product is independently assessed and certified, ensuring consistent safety, quality, and environmental performance.

In the early 2000s, the PVC industry faced scrutiny over health and environmental risks. In Australia, over 75% of PVC products are used in the built environment, mainly as pipes, conduits, and fittings.

The Green Building Council of Australia (GBCA), working with PIPA and the Vinyl Council of Australia, reviewed the full lifecycle of PVC—from raw materials to end-of-life—and established Best Environmental Practice (BEP) PVC. These requirements were adopted across Australian standards, allowing combined certification and simplified marking for products meeting both plumbing and environmental standards. PIPA continues to collaborate with the GBCA under their Responsible Products Framework.

In May 2024, AS/NZS 5395 was published, creating a single, comprehensive standard for BEP PVC pipes, conduits, profiles, and fittings—ensuring consistent safety, quality, and environmental responsibility across the industry.

PFAS (per- and polyfluoroalkyl substances) have raised global health and environmental concerns, but they are not used in the manufacture of plastic pipes and fittings (PE, PP, PVC, or PEX) in Australia. Independent research also shows that PFAS are unlikely to permeate undamaged PE or PVC water pipes.

Plastic pipes are manufactured to strict Australian Standards, are independently certified, and provide safe, durable, and sustainable solutions for delivering drinking water and essential services.

Corrosion has a significant impact on Australia’s water infrastructure. The Australasian Corrosion Association (ACA), using data from the National Water Commission and the Water Services Association of Australia (WSAA), estimates the aggregated cost of corrosion in the water sector at around $1 billion per year.

Every year, there are approximately 33,000 water main breaks—roughly one every 16 minutes—with 80% caused by corrosion. These figures highlight the importance of durable, corrosion-resistant solutions like plastic pipes for long-term water infrastructure.

The Utah Water Research Laboratory at Utah State University conducted a detailed study on water main break rates in 2011, 2018 and 2023, analysing data from a large number of utilities across the USA and Canada. The most research highlights the ongoing challenges of aging water infrastructure and the critical role of pipe material in system reliability.

Key findings include:

PVC pipes perform best, offering a durable, corrosion-resistant solution for long-term water infrastructure.

Source: Water Main Break Rates in the USA and Canada: A comprehensive Study Dec 2023, Utah Water Research Laboratory, Utah State University

Research by Steve Folkman, Utah State University, validates the long life of PVC pipes. While the average failing water main is just 47 years, studies worldwide confirm that PVC pipes consistently exceed 100 years in service. These findings are based on real-world “dig-up” studies of pipes installed by contractors, proving PVC’s durability and reliability for long-term infrastructure.

The story is similar in the United States. A 2002 report, titled “Corrosion Costs and Preventive Strategies in the United States”, mandated by Congress and released by the Federal Highway Administration, revealed that corrosion costs the US water industry a staggering $36 billion every year.

Note: Numbers are in USD.

Compared to other pipe materials, plastic pipes have the lowest failure rate for pressure water applications

Plastic pipe systems consistently have the lowest failure rates in water infrastructure compared to cast iron, ductile iron, steel, and asbestos cement. Whether it’s PE or PVC, plastic pipe systems consistently deliver the best performance worldwide.

Between 2005 and 2007, CSIRO partnered with the American Water Works Association Research Foundation (AwwaRF) to study the long-term performance of PE pipes. The research highlighted their extremely low failure rates compared to other pipe materials, confirming PE as a highly reliable choice for water infrastructure.

Plastic pipes have a long service life and are not discarded as plastic waste.

When people hear “plastic,” they often think of single-use items like bags or bottles that can end up as litter. Plastic pipes are completely different. They’re engineered for strength and longevity, designed to stay in service for decades—not tossed away after a single use. That’s why they don’t contribute to plastic pollution in our oceans and waterways.

Did you know? Plastic pipes make up only a tiny fraction of waste going to landfill.

A NSW Government audit of construction and demolition waste found that at one landfill site handling 600,000 tonnes of material, just 1,000–3,000 tonnes were plastic pipes—that’s only 0.1–0.5%!

Why so little? Because plastic pipes are built to last. With a service life of 100 years or more, most are still in their first life cycle today. That durability is exactly why they’re such a smart choice for building and infrastructure projects.

Our Commitment to Recycling

At PIPA, our commitment to the Australian community is simple: recycle as much usable plastic pipe as possible.

Plastic pipes have exceptionally long service lives, so they make up only a small fraction of waste streams. That’s why our industry works closely with waste management companies, major distributors, and key clients to collect end-of-life pipes, off-cuts, and other recyclable materials viable for designated recycling.

By closing the loop on plastic pipes, we support a truly circular economy for Australia’s infrastructure.

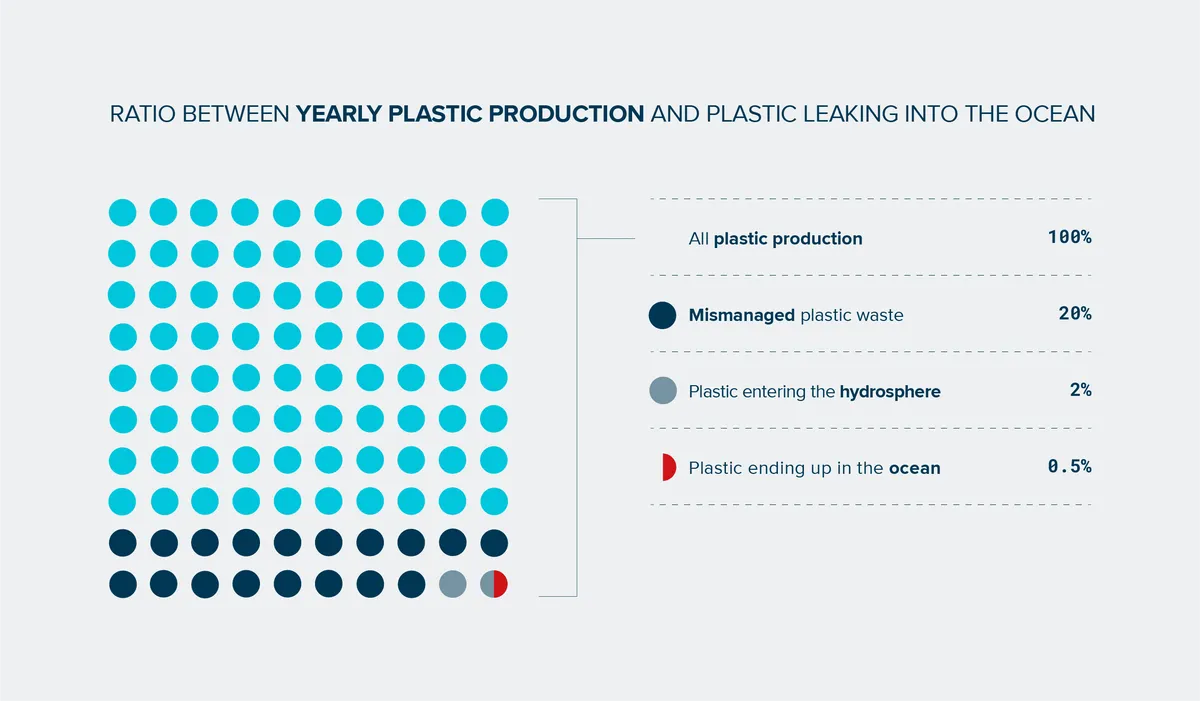

Every day, plastic leaks into the ocean from thousands of sources worldwide. While the numbers sound alarming, less than 0.5% of the 400 million tons of plastic produced each year actually ends up in the ocean. That’s because only a small share of plastic is mismanaged, and an even smaller amount reaches waterways.

Still, the impact is significant. Most ocean plastic sinks or washes onto coastlines within a month of entering the water. Around half sinks immediately, while about 80% of floating plastic beaches locally, creating serious problems for coastal ecosystems, tourism, fishing industries, and local communities dealing with high cleanup costs.

Plastic pipes are not part of the plastic waste pollution breaking down into microplastics in our oceans.

Research shows that plastic pipes don’t contribute to ocean or waterway pollution. Thanks to their durability, long lifespan, and specific applications, they’re unlikely to end up as discarded consumer waste.

A 2017 Norwegian study tested raw, treated, and tap water for microplastics and found that in the majority of all samples, no microplastic particles could be detected or quantified.

Two studies, in 2020 and 2021, carried out by TEPFFA tested various plastic pipes for microplastics in drinking water. Both found no detectable particles, confirming that these pipes don’t release microplastics into water.

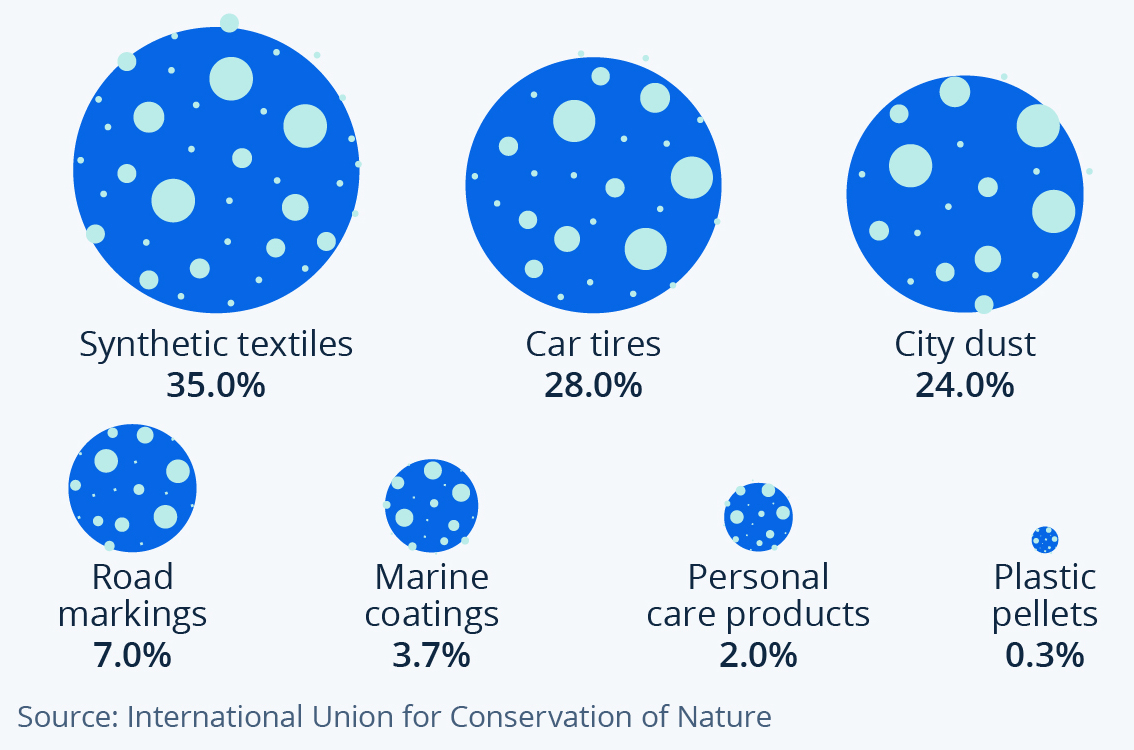

Where the Ocean’s Microplastics come from?

Estimated share of total microplastics in the world’s ocean, by source

PIPA is proud to support Operation Clean Sweep, a global initiative dedicated to preventing plastic pellet loss. We work closely with our members across Australia—both current partners and those working towards joining—to reduce pellet loss throughout the supply chain. At PIPA, we believe every organisation has a role to play, and even small actions can create meaningful, measurable change for the environment.

What does this campaign aim to achieve?

To support every plastic resin handling operation—whether manufacturing, transporting, fabricating, or installing—in adopting best-practice housekeeping and containment measures, to work towards achieving zero pellet loss.

Plastic pipes are the preferred choice because they’re durable, long-lasting, easy to install, energy-efficient, recyclable, and cost-effective—delivering reliable performance you can count on.

Sources: National Water Report. Presentation by Sydney Water to PIPA (2013).

“With the new pipes having an approximate lifespan of up to 100 years, this project ensures we can keep providing our customers in the Wilmington area with trusted water services for years to come, as well as limit the potential for water main breaks and leaks on a busy regional road”

Amanda Lewry – SA Water’s General Manager Sustainable Infrastructure